Tunnel Entrance Safety System (TESS): Revolutionizing Car Wash Safety and Efficiency

Introducing a one-of-a-kind system designed specifically for conveyor car washes that will make damage claims due to loading a thing of the past.

With multiple cameras at the tunnel entrance feeding to a server with proprietary computer vision logic, the system is able to detect specific conditions that can lead to issues in the wash. TESS then signals the tunnel controller to activate the e-stop to prevent a mishap. This patented technology can also detect vehicle conditions through AI and machine learning to subsequently activate tunnel retracts for vehicles that require them.

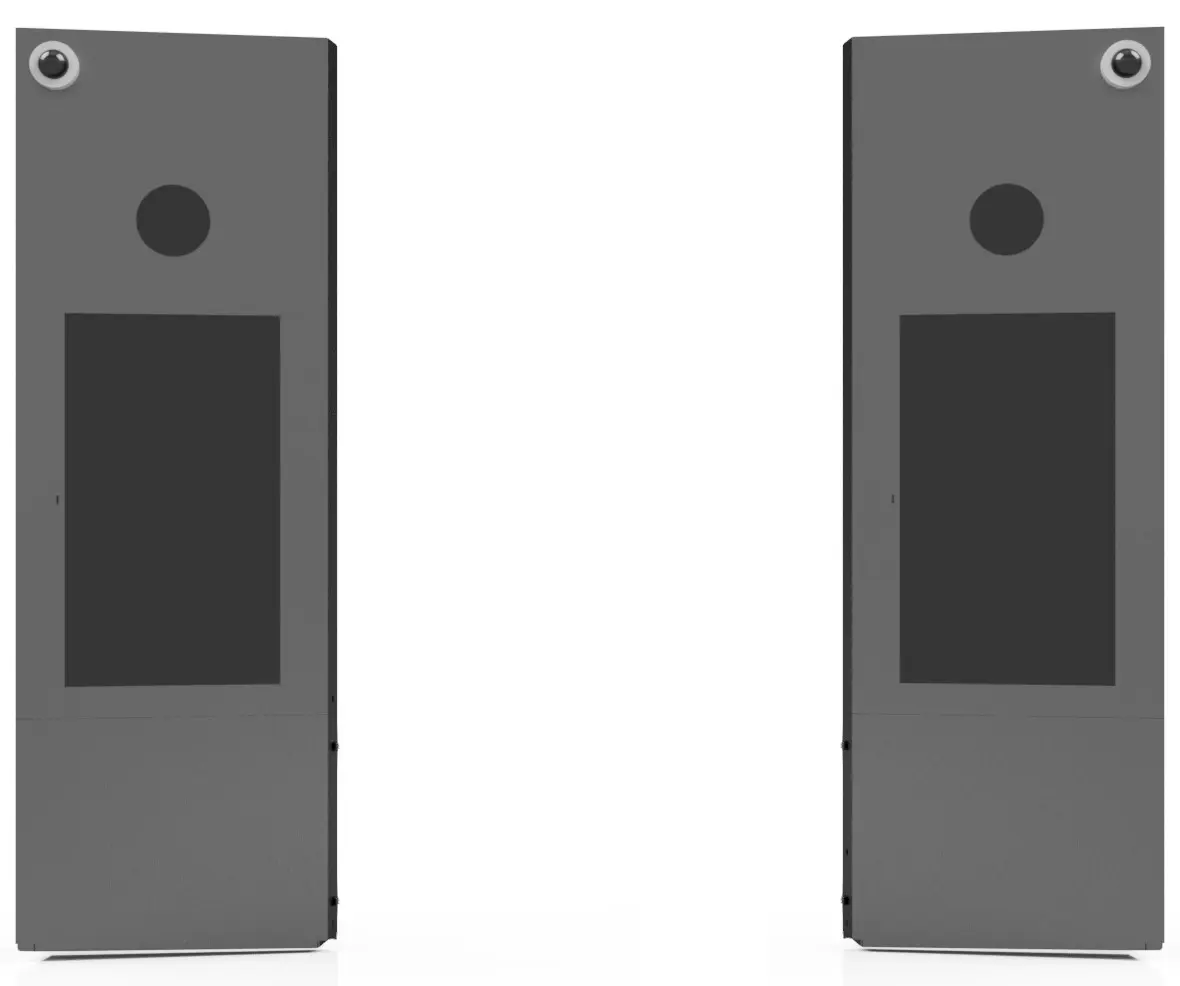

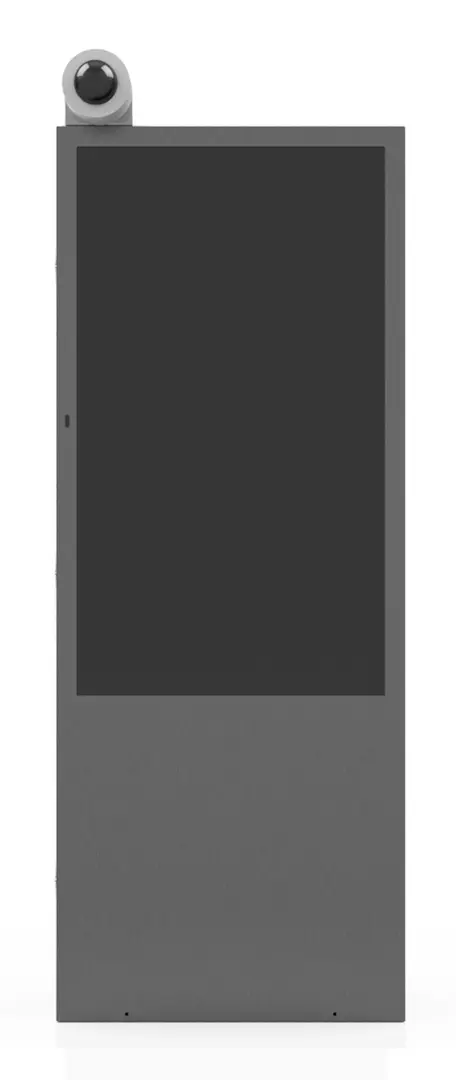

TESS makes a powerful first impression for customers entering your car wash tunnel! Sleek and durable stainless-steel columns with IP67 rated displays with visual loading and voice commands guide customers onto the conveyor for a smooth and pleasurable car wash.

Tunnel Entrance Safety System (TESS)

Tunnel Entrance Safety System

2.0 Dual (TESS 2.0)

- Audio integration with tunnel control system to announce car wash and direct customer

- Video feed of driver’s and passenger’s side where vehicle transitions to conveyor

- Video integration with tunnel control system to display car wash service

- Front and rear access to cabinets for serviceability and maintenance

- Sloped column bases are easy to install and reduce need for shimming

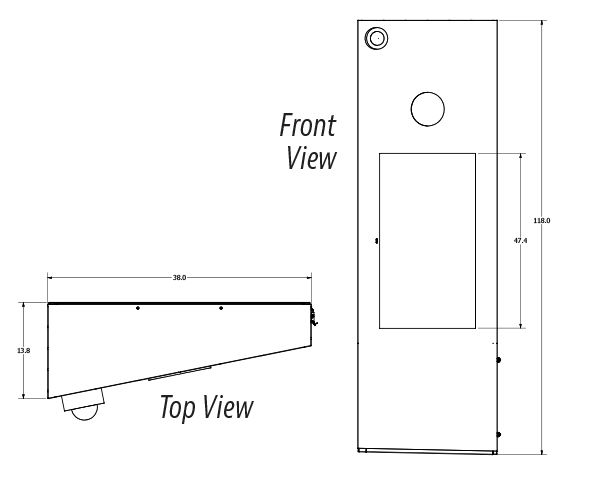

Construction: Stainless steel

Dimensions: Frame 25”W x 72”H x 7”W Screen size 55” Diag – 47.5”H x 26.5”W

Electrical Input: 100-240 VAC 6 AMP

Temperature: Operating: -30°C to 50°C

Digital Media: Includes 3 hours support for digital media content development

Tunnel Entrance Safety System

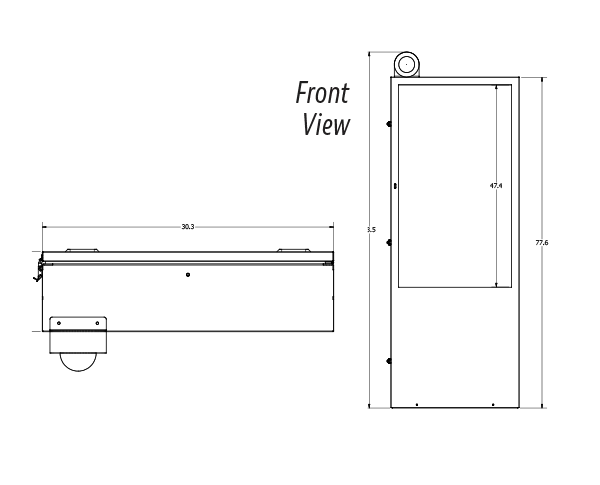

Compact (TESS-Compact)

- Audio integration with tunnel control system to announce car wash and direct customer

- Video feed of driver’s side where vehicle transitions to conveyo

- Video integration with tunnel control system to display car wash service

- Rear access to cabinets for serviceability and maintenanc

Construction: Stainless steel

Dimensions: Frame 30.3”W x 77.6”H x 8.2”W Screen size 55” Diag – 47.5”H x 26.5”W

Electrical Input: 100-240 VAC 6 AMP

Temperature: Operating: -30°C to 50°C

Digital Media: Includes 3 hours support for digital media content development

Tunnel Entrance Safety System Add-Ons

PBS 4000 (TESS 2.0 only)

- PBS 4000 integrates directly into TESS cabinet for convenience and accessibility

- Reduces installation cost and complexity for wiring of control panel

Kesseltronics Panel/Node Integration

- Significantly reduces installation cost as single network cable to MCC is needed instead of numerous separate home runs

- Node placement in proximity to other sensors provides convenient access point

Entrance Eye Module

- Entrance eyes integrated into TESS cabinet protects hardware and wiring from damage and corrosion

- Reduces installation cost

Tire Detection Sensor

- Tire sensors integrated into TESS cabinet protects hardware and wiring from damage and corrosion

- Reduces installation cost

Truck Bed Sonar

- Truck bed sonar integrated into TESS cabinet protects hardware and wiring from damage and corrosion

- Reduces installation cost

Full Facility Monitoring Module

- Health check for entire facility including alarm system, camera system, etc

- Supports full facility preventive maintenance with alerts to drive adherence

Some key features and benefits:

- Supports infinite dilution and dispensing rates, allowing precise control over resource use from any web enabled device.

- Seamlessly adjusts chemical, water, and air flow without manual input or physical swapping of parts such as injectors or metering tips.

- Identify problems in the tunnel when chemical is not pulling at the specified level.

- Utilize any brand of chemical in your wash! Spot-On is not affiliated with any chemical providers.

- Feedback loop ensures that desired setpoints are being met and will alert operators of anomalous conditions.

- Manages the cost of resources and mitigates environmental concerns due to overuse of chemicals and water.

- Able to adapt as cleaning needs change, be it seasonally, through vehicle. recognition for optimal cleaning setup, or recent weather conditions.

- Offers user-friendly convenient navigation with intuitive design.

- Personalized Dashboard displays performance metrics aligned with your business goals and operations.

- Multi-site operators seamlessly navigate between locations, viewing operations across all sites.

- Provides vital insights on system health, along with robust auditing and security controls.

- Monitoring capability can be extended to any device on the network (ex. motor control cabinet).

- Health alerts and error conditions visible in the dashboard for all equipment in the ecosystem.

- Supports sensors for water and gas service for measurement of true overhead cost.

- Security and auditing controls to monitor user access.

“TESS combined with No Pile Ups ensures that we do not have costly accidents in the tunnel, for example, where a car is misaligned and drifts off the conveyor. Those types of situations never occur with these systems in place.”

Kent Presley, Big Splash Car Wash“We love the flexibility that our self-loading TESS cabinets offer. We can run with or without a loader allowing us to be more flexible with staffing. The screens help customers align cars on the belts and our chain conveyors without relying on hand signals from wash attendants. The signals and instructions from the TESS are 100% consistent. Customers never have to wait. The self-loaders are always in position, giving instructions.”

Dan Nebeker, Shiny Shell Car Wash